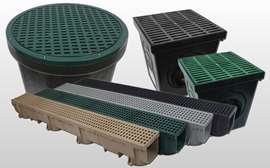

Featured Products

Shop By Category

SEPTIC SOLUTIONS, INC.®

SHOP OVER 1,500 WASTEWATER & SEPTIC PRODUCTS!

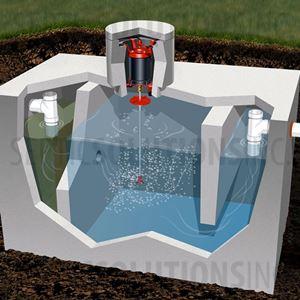

Septic Solutions® is the largest online distributor of Aerobic Septic System Parts, Septic Tank Parts, and Septic Supplies. With over 1500 wastewater and septic system related products, we have the largest online selection for your wastewater and septic system needs. These products include septic air pumps, septic aerators, air pump repair parts, submersible pumps, alarms and control panels, septic tank risers, septic care products, effluent filters, vent pipe odor filters, and much more! We have an ever expanding line of plumbing supplies such as submersible pumps, alarms, complete pump systems, and more! We also have an extensive line of pond aeration and maintenance products! We offer fast and free same day shipping on most items!

FAMILY OWNED COMPANY WITH OVER 125 YEARS OF COMBINED EXPERIENCE!

Our company was founded in 1989 by the James family. All 5 members of the family continue to own and operate the business today! We have the experience and we know the products. You can trust Septic Solutions, Inc.® to provide you with the high quality products and customer service that you need.

In 2003, we began our online store to serve customers nationwide and even worldwide. Our goal was to offer a wide array of septic system products for every application at the lowest possible prices. We strive every day to meet this goal and bring you the highest quality products at the lowest prices on the market.

WE STAND BEHIND THE 1,500+ PRODUCTS THAT WE SELL!

One of the advantages of purchasing your septic system products from Septic Solutions® is that we know the products we sell. Septic Solutions® is owned and operated by a family that has been installing, servicing, building, designing, and selling septic systems and supplies since 1989. We know the products we offer because we have been using and maintaining most of them for many of those years. During that time we have discovered what products work and what do not, what products last for extended periods of time, and what products do not.

Septic Solutions® is dedicated to make sure your online shopping experience for anything related to a Septic System will be a happy experience insuring that you will come back to us when you need more supplies and that you will tell your friends and neighbors how easy it was to purchase great products at very reasonable prices from Septic Solutions®. Please know that all of us at Septic Solutions® truly appreciate your business and will be here to support you and the products we sell for many years to come.

"SEPTIC SOLUTIONS, INC." is a federally registered trademark with registration number 3,215,128 owned by Septic Solutions, Inc.

"SEPTIC SOLUTIONS" is a federally registered trademark with registration number 3,731,246 owned by Septic Solutions, Inc.

"ULTRA-AIR" is a federally registered trademark with registration number 4,763,426 owned by Septic Solutions, Inc.

"SEPAERATOR" is a federally registered trademark with registration number 4,763,454 owned by Septic Solutions, Inc.

The content of this website is protected by Federal Copyright Registration TXu 2-030-959 owned by Septic Solutions, Inc.